Whether youre building out a grow room at home or for commercial use there are a few things you should consider for finding a space for germinating growing and harvesting flower. Starrcos commercial grow room setups are built and installed 75 percent faster than conventional construction methods.

Modular Cannabis Grow Rooms Cultivation Rooms Porta King

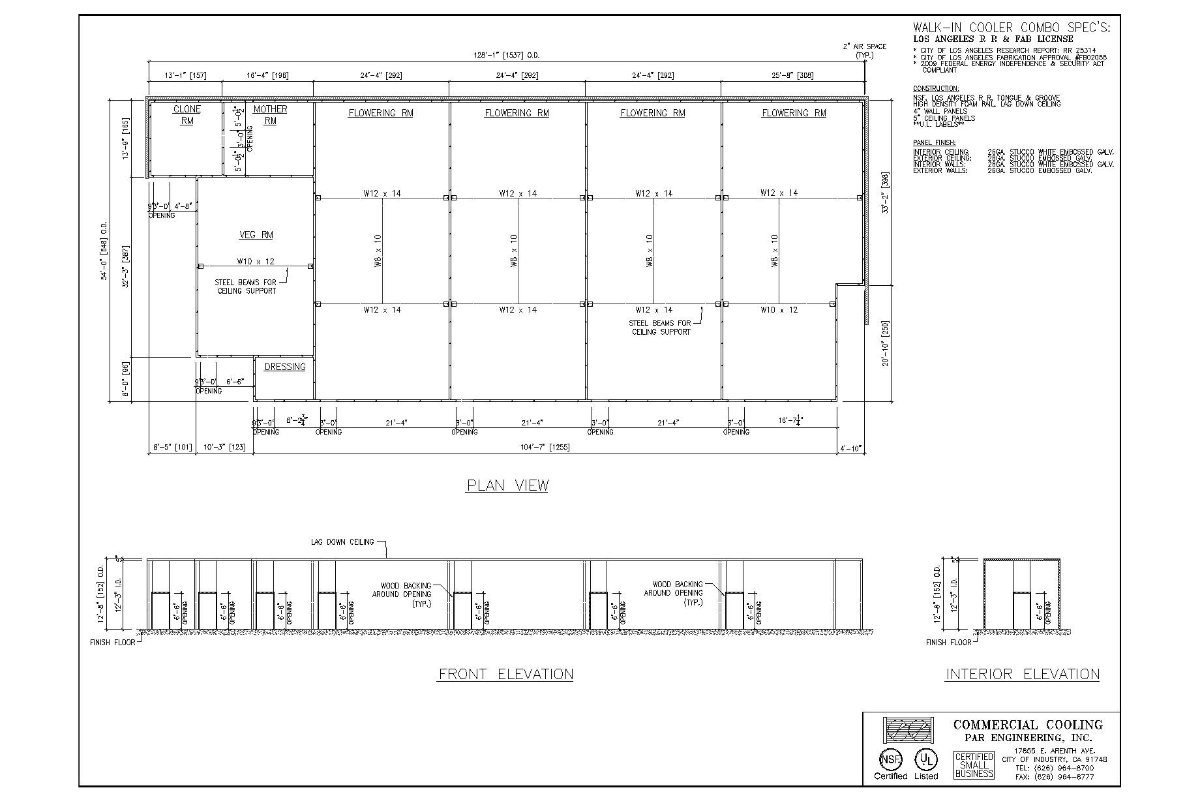

Compressor room packing room central corridor housing air handling units and pipelines.

. Warehouse rent per year 50000 Build out 60000. Commercial grow room setup all starts with the design. Growing together from the ground up.

A commercial grow room is a designated area in which plants are germinated grown and ultimately brought to flower. Rails carriages and vertical racking or shelving. Commercial cannabis grow room designs meet the most stringent of regulatory environments whether they are energy efficiency goals code required Good Agricultural Practices GAP or Good Manufacturing Practice GMP certification.

Grow room design for marijuana growing is easy for beginners or advanced gardeners alike. Grow 30 delicious veggies fruits and herbs in just 1x2 of space. Louis MO factory using accelerated production processes.

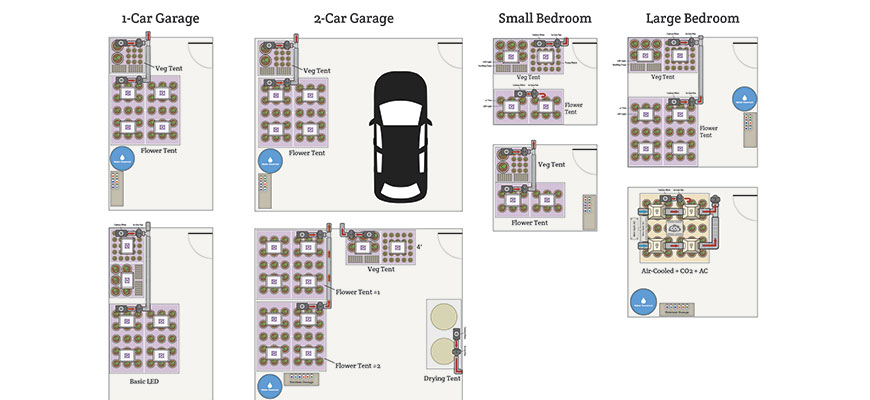

Designing a marijuana grow room comes with many different options in terms of location. Outdoor plots will cost 10 to 17 per square foot while a greenhouse will charge about 50 per square foot. We are going to show you some designs you can copy for your own room based off a 15 x 15 room.

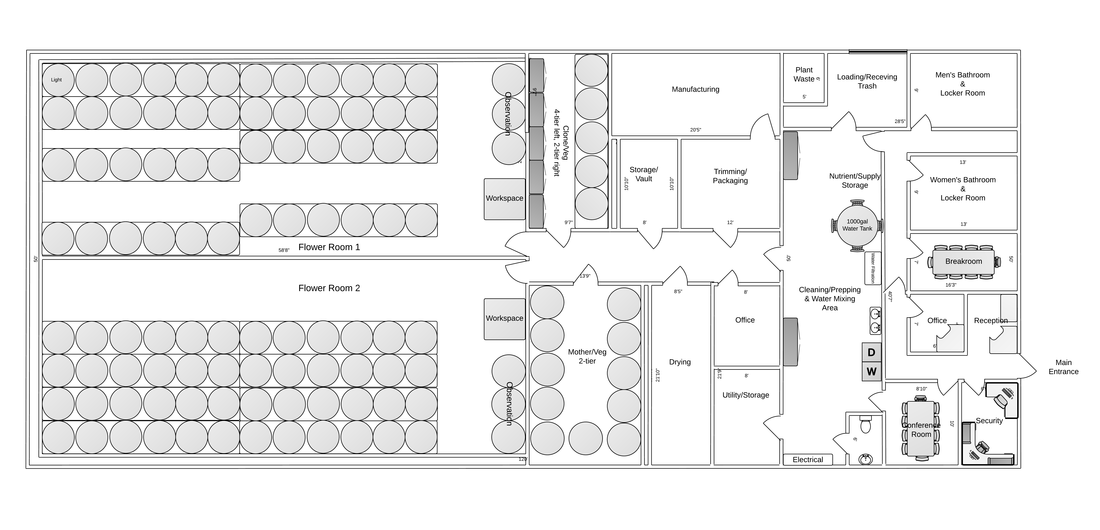

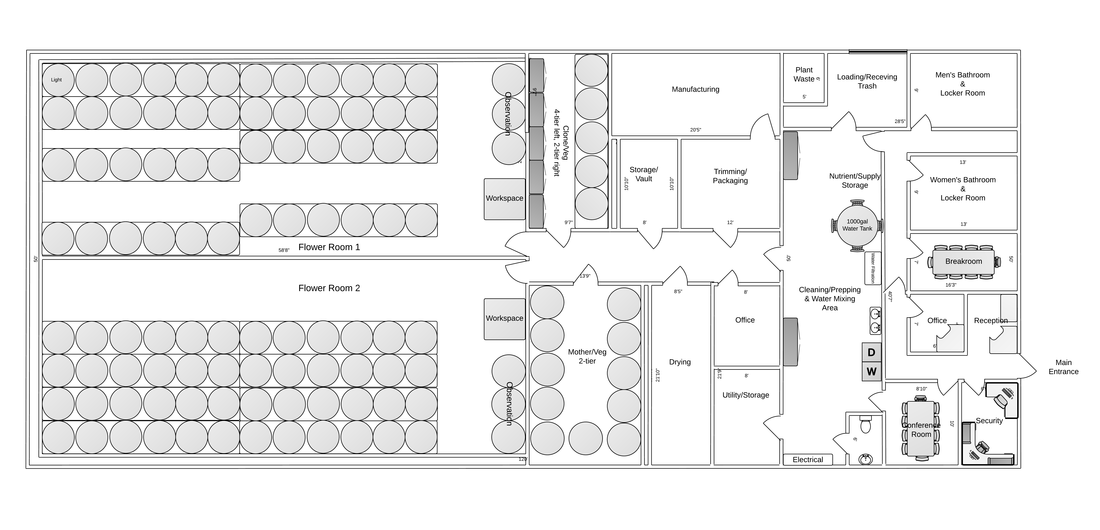

Draw up a plan of the floor space and figure out how many plants you can grow in that space. Lets evaluate the light levels in the room starting with the average value at 15 m5 ft high crop height. Large Grow Room Design Examples.

Facility The decision to grow indoors in a greenhouse or outdoors will determine your facility location and setup. Constructed of heavy-duty steel GROW vertical racking is designed to provide stable long-term support for plants and accessories. Home - ASHRAE Oregon Chapter.

Grow room design blue prints. There are a few key components to consider when designing a efficient and sustainable commercial grow room such as how much space is required how to water crops how to provide power and how to properly light the space. These 5 different plans are simply a complete grow op parts list.

Insulted doors central chilling station ammonia or freon based air handling units computer based controllers optional racks and trolleys harvesting trays etc. If you are lucky enough to have a larger room to grow in you can get really creative with your setup. Would also be required.

You will then need to take into consideration the spacing and height of your trays for ease of access without sacrificing space and yield. The cultivation consultant will teach you about day-to-day workflow and. We help commercial cannabis growers adapt dirty spaces into hyper-clean grows.

Your layout can also be custom designed with viewing windows for each grow room and workspace to prevent contaminants from spreading through open doors. Ad See how green construction is revolutionizing the industry and how top firms are preparing. These set ups take more time money to get them from just a Pile Of Grow Parts turn them into a completed grow rooms set ups.

Ultra clean environments support ecosystems with fewer pesticides microbes insects mold. Typical Commercial Grow Room Setup Cost. Each modular building is manufactured at our St.

8 x 8 grow tent setup and design. Ad Big enough to feed the family small enough to fit in any home or apartment. For example undersizing the environmental controls is an.

Typically indoor cannabis cultivation has at least eight spaces or more flower rooms with a standard measurement of 30 feet across and between 50 to 100 feet long. Some cultivation businesses have failed because of poorly considered layouts and mechanical systems that are difficult to change once the site is set operational. Our modular grow rooms provide airtight seals T-grid lighting mounts and self-sufficient air filtration systems.

HVAC energy optimization Careful selection of temperature RH and VPD is critical to reduce capital operating costs. Get best practices for implementing green construction as global demand continues to grow. Propel your companys growth in todays competitive market.

The differences between growing cannabis at scale and growing cannabis in a backyard garden are vast. No water line needed. A proper design should streamline workflow and allow for the best movement around your facility.

Prepare the facility design plans and the list of equipment hardware and supplies youll need to operate. Commercial Grow Room Design Plans Cannabis Facility Design. The finished parts of the modular grow room are shipped to your facility for installation.

Cannabis Grow Room Design. The grow room climate must be controlled to achieve effective yields Temperature Humidity Vapor Pressure Deficit Lighting can be reduced too far. Standard commercial grow room design plans does vary depending on your crop and your cultivation practices.

Will you be using hydroponics or standard soil medium. A cultivation consultant should be able to walk you through the pros and cons of each approach so you can choose the one thats best for you. Buildings meanwhile typically demand 75 per square foot.

The sky is the limit and you can have as few or as many tents as youd like. Our cannabis vertical grow system consists of 3 main components. Although this will impact your commercial grow room setup cost you will be happy you did.

If you opt for indoors here are five pointers. There are many ways to successfully grow commercial cannabis. Still when it comes to a cannabis cultivation facilitys actual design you might be out of your league.

Some products have a long lead time so factor that into your timeline. Using the same amount of fixtures per surface you see a difference of 75 μmol s-1 m-2 between the 2 lamp room 888 μmol s-1 m-2 and the 10 lamp room 963 μmol s-1 m-2. Thats 85 more light in.

Youre probably somewhat familiar with the methods and the equipment required of a functioning commercial grow room. Cannabis cultivation facility design is a part of the business planning process that is worthy of very deep consideration.

Commercial Grow Room Design Plans For Indoor Facilities

Indoor Grow Room Design Setup Samples Hydrobuilder Learning Center

Commercial Grow House Building A Grow House Coastal Steel Structures

Cannabis Facility Design Free Consultation With Led Expert Jennifer Martin Cultivation Consulting

Cannabis Cultivation Coolers Storage Freezers Commercial Cooling

Commercial Grow Room Design Plans In California

Cultivation Facility Design Next Big Crop Industry Expertise

0 comments

Post a Comment